large cars

Driving school

theory book

for category C - D - C/E - D/E

Large cars and lorries

5. The load-bearing parts of the car.

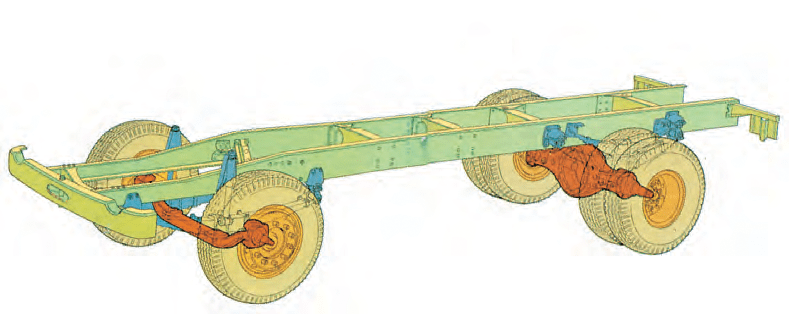

The load-bearing parts of the vehicle include chassis/self-supporting structures, wheels (including tyres, rims and wheel bearings) and suspension (including axles, spring brackets, spring bolts, lugs, springs and shock absorbers) and bogie structures.

The weight and load of the car is transferred to the road through the load-bearing parts.

Chassis frame.

You have to control:

The chassis frame must not be deformed, cracked or otherwise damaged.

Signs of failure:

- Cracks in the paint or concentrated rusting on the chassis frame or springs can be caused by breakage. Rusting around bolts and rivets indicates that they have loosened due to wear and tear from lack of maintenance.

Suspension

The function of the spring system, together with the shock absorbers, is to even out or absorb the forces that occur when driving on uneven roads and to ensure that the wheels are in contact with the road surface. The spring system must also transfer the forces that occur during starting, braking and cornering. Leaf spring suspension and air suspension are the most common suspension systems.

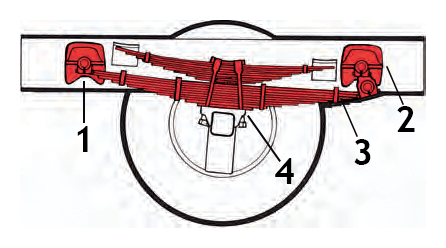

Leaf springs

Leaf springs can vary in shape, but usually a leaf spring consists of several spring layers of different lengths connected together, and the top spring layer (the guide layer) is usually fitted with an eye. The spring is attached to the chassis frame at the front with a spring bolt and at the rear via a sliding joint or linkage. The spring is also attached to the axle with a cable tie.

Checking the suspension:

- The individual layers of the leaf spring must not be broken.

- The axle must be clamped to the spring.

Signs of failure:

- Oil extraction on shock absorbers indicates a defective shock absorber.

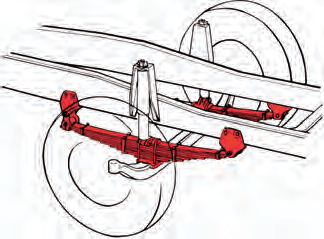

Air suspension

Air suspension systems basically consist of a number of air spring bellows attached between the chassis frame and the wheel axle. Since air bellows can only absorb vertical forces (carrying the car and load), the system is supplemented with reaction arms to absorb the forces generated during starting, braking and cornering. The spring bellows contain compressed air and the pressure is regulated through valves according to the car's load.

Checking air spring bellows:

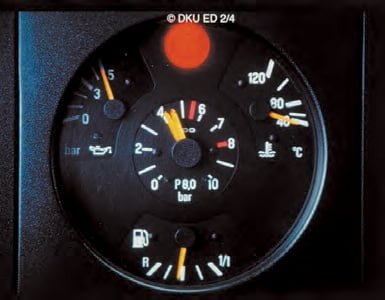

- Air spring bellows must be tight. Leaks will be audible as a hissing sound. With larger leaks, the car will become "warped" and the pressure gauge will show abnormally high air consumption.

Bogie axles

A bogie is a system where a single axle is replaced by two or three axles to increase the load capacity of the vehicle. In some bogie designs, one or two of the axles can be lifted off the road, which can be an advantage when driving without a load. One of the axles can be self-steering, which has a favourable influence on the car's handling, especially when driving with a load and at low driving speeds.

Lifting one axle increases the pressure on the other axle. This provides better traction, which can be important when travelling in slippery conditions or in situations where the car is stuck.

Driving with a lifted axle also reduces wear and tear on tyres and suspension, but also poses a risk because the driving characteristics of the car, including handling, are altered. This is mainly due to the altered (shorter) wheelbase and the weight of the rear overhang.

When driving with a lifted axle, the maximum permitted axle load on the other axles must not be exceeded.

Other legal provisions on suspension:

- The car must have suspension on all axles.

- There must be no significant play in the suspension as a whole or in its individual parts due to wear or similar.

- Lorries must be equipped with shock absorbers at the front wheels. The same applies to buses over 5 tonnes gross vehicle weight.

Buses up to 5 tonnes gross vehicle weight must be equipped with shock absorbers on all wheels. - In practice, there are always shock absorbers on all axles when the vehicle has air suspension.

Wheels and tyres

Wheels and tyres are the parts that, in addition to carrying the car, also make contact with the road surface and transmit the forces that occur during acceleration, cornering and braking.

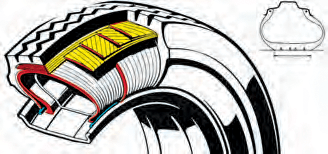

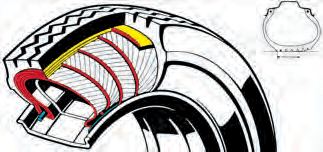

Tyre types

There are three types of tyres: radial, bias, off-road and winter tyres.

Off-road and winter tyres are a breed apart, as these tyres have a deep and open tread pattern that allows them to better grip the loose surface. However, this advantage disappears if the tread pattern becomes filled with snow or dirt.

Checking wheels and tyres:

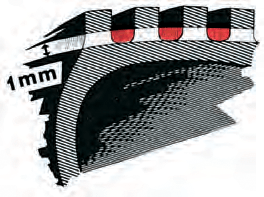

- Tyres on all wheels must have a minimum tread depth of 1 mm in the main tread pattern, be free of damage and the tyre should not be worn unevenly. However, buses up to 3500 kg gross vehicle weight must have a tread depth of at least 1.6 mm.

- Hub and wheel nuts must be shielded by a wheel cover or similar if they are outside the tyre's outer surface.

Legal provisions:

- Tyres, rims and wheel bearings must be undamaged.

- Tyres must have a load capacity as stated in the tyre labelling. Tyres on the same axle must have a combined load capacity that is at least equal to the permitted axle load. Tyres must also be of a size and shape that corresponds to the rim.

- Tyres on the same axle must be of the same size and type.

- Tyres must be inflated to the manufacturer's recommended pressure (tyre pressure for each car should be stated in the owner's manual, otherwise ask your car dealer or garage).

Signs of failure:

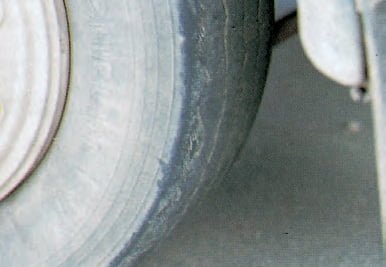

- Uneven/skewed tyre wear is often caused by incorrect steering dimensions, the vehicle's wheels not tracking, defective shock absorbers or the axle has shifted on the springs.

When hitting a kerb or similar, damage to the tyre can occur, which can be seen as a bulge in the tyre sidewall.

Abnormal tyre shape:

- Abnormally hot tyres after driving for some time or a tendency for the vehicle to pull to one side indicate incorrect tyre pressure, which can damage the tyre in the long run. In this case, the tyre pressure should be checked using a tyre pressure gauge.

Underinflated tyres can cause twin tyres to work against each other, causing wear and heat, which can lead to tyre burst or fire in the tyres.

- Shaking and vibrations in the front tyres can be a sign of suspension failure or wheel imbalance.

Risk factors for load-bearing parts

- Driving with tyres that are not designed for the vehicle and driving purpose in question carries a risk of tyre damage and possible tyre blow-outs.

- Driving with damaged tyres can also lead to the risk of tyre blowouts.

- The tyre blowout will usually happen at high speed and therefore the consequences are all the more severe, especially with tyres on steered axles.

- Faults in load-bearing parts (suspension, bearings, etc.) lead to a risk of breakdown.

- Failure to brake the vehicle when changing tyres poses a risk of damage to the vehicle and people.

Test your knowledge

Cat. C - D - C/E - D/E - D/E - Section 5

Select the questions you think are the right ones.